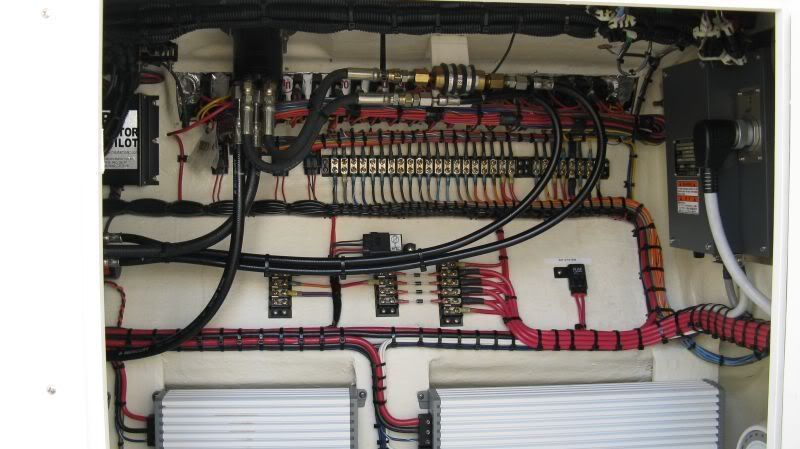

ABYC rules is no solder, it will break under stress

go crimping

Porsche switch to crimping on all their race cars years ago, they found the solder connection failing

go crimping

Porsche switch to crimping on all their race cars years ago, they found the solder connection failing

Comment